I will start off by saying this: all book binding glues are not created equal.

In our 90 years in business, we have worked with hundreds of book binding companies.

Like many of our customers, we're always working to get competitive pricing on our raw materials. It's only natural to shop around for the best pricing possible. But one thing we have noticed is that some book binders are making the switch to different glue vendors because, on the surface, the price per pound for their glue is less expensive.

In the end, it turns out that's really not the case. Here's a little story for you...

One of our customer’s switched to one of our low cost protein glue competitors. This competitor does sell their product at about 10-20% lower than ours, which cost the customer $300.00 less per skid than a skid of our glue. That's a great savings (it seems). But that does not tell the full story.

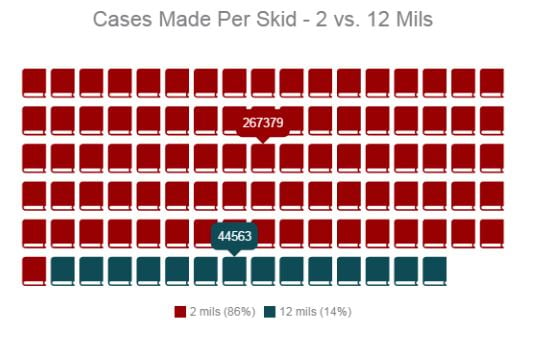

We were able to attend a glue trial with this customer that we lost to this low cost glue provider. Yes, on paper our competitors glue was less expensive than ours. But when comparing our glues side by side, the customer needed to use much more of the cheaper glue to get the same performance that they had with ours. They were using 12 mils of the competitor’s glue when they only required about 2 mils of our glue for the same performace. Yes, you read that right. They needed 6x more of the cheaper glue to keep up with the performance of ours. (This was measured with a mil depth gauge).

Not only did the customer need to use more of the competitors glue for their application, but they also had to consider the implications of using more glue - specifically board warping.

The Cost Breakdown

So what does that mean for the customer that switched?

Assuming glue film thickness on a sheet size of 7.75 X 11.125 for a run of 5,000 pieces, our 2,000 lb. skid would make 267,379 cases. If our protein glue is $.95 per pound, the customer would spend $1,900 for one skid of glue.

The competitors 2,000 lb. skid would make only 44,563 cases. If their protein glue is priced at $.80 per pound, the customer would need to spend $9,600 to make the same number of cases that our glue made. They would need six skids of the competitors glue to match our one skid.

More on this example can be found below.

Cost Benefit of Using Less Glue

Using reduced film thickness will really be the cost saver for your business.

Every 1 mil of glue added to film thickness increases the amount of product used by approximately 3.8 lbs. per thousand cases produced. Here is the above example in more detail.

Assuming glue film thickness on a sheet size of 7.75 X 11.125 for a run of 5,000 pieces:

@ 1 mil = 18.7 lbs. of glue used = 1 skid makes 534,759 cases

@ 2 mil = 37.4 lbs. of glue used = 1 skid makes 267,379 cases

@ 3 mil = 56.1 lbs. of glue used = 1 skid makes 178,253 cases

@ 4 mil = 74.8 lbs. of glue used = 1 skid makes 133,689 cases

@ 5 mil = 93.5 lbs. of glue used = 1 skid makes 106,951 cases

@ 6 mil = 112.2 lbs. of glue used = 1 skid makes 89,126 cases

@ 7 mil = 130.9 lbs. of glue used = 1 skid makes 76,394 cases

@ 8 mil = 149.6 lb of glue used = 1 skid makes 66,845 cases

@ 9 mils = 168.3 lb of glue used = 1 skid makes 59,419 cases

@ 10 mils = 187 lb of glue used = 1 skid makes 53,479 cases

@ 11 mils = 205.7 lb of glue used = 1 skid makes 48,614 cases

@ 12 mils = 224.4 lb of glue used = 1 skid makes 44,563 cases

Of course, glue cost is a very important detail to consider. Just make sure before you switch that you are not sacrificing glue performance and quality, as this will end up costing you much more in the long run.

If you have questions about our book binding glues, feel free to contact our team to learn more.

.png)