If you are in the book binding business, case board warp is something you are probably familiar with. If you work with case board, you may have experienced warp issues. We recently visited with a case-making customer that was experiencing case board warp. Like many who have been in a similar situation, this customer looked to their board and glue suppliers as resources for understanding why case board warps.

What is case board warp?

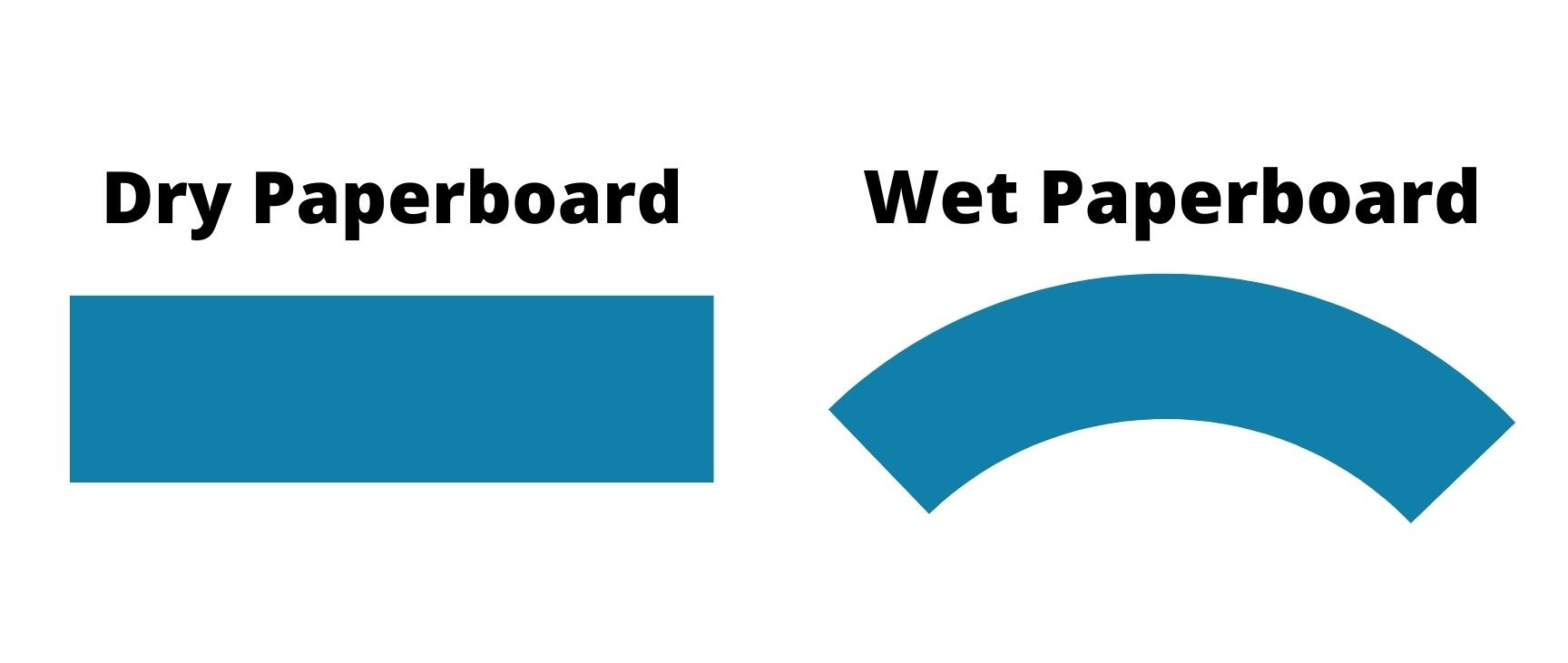

Case board warp happens when the board becomes bent, curled, or distorted somehow. Most times, board warp can be attributed to moisture. Paper and paperboard are made from cellulose fibers, which have a tubular shape. When around moisture, these fibers will absorb water, causing the fibers to increase in diameter considerably.

However, low moisture can be just as problematic. At paper mills, paperboard is carefully fine-tuned to its required moisture content. The pallets are then shrink-wrapped to retain that correct balance for as long as possible.

When the board arrives at the book binder, it could be stored in an unheated warehouse or a tropical climate; both scenarios widely differ from the moisture content the paperboard requires. Many of our customers have issues with board warp in the winter months when there is very low humidity outside, making the environment very dry.

The Science Behind Board Warp

All paperboard manufacturers use paper waste to create new paperboard, which is derived from recycled materials. While this is beneficial for the environment, it is hard to control the consistency of the paperboard.

Every time paper gets recycled, its fibers get shorter and shorter. Long fibers are more stable in comparison to short fibers because they don’t get saturated with moisture as quickly. Nowadays, all case boards are made from recycled materials, which have sometimes been recycled up to 15 times, making the fibers short and more reactive to moisture.

Ways to Limit Board Warp

- The moisture percentage in the board fibers is delivered at a specified range. Since the environment will affect the reaction of moisture loss or absorption, it is essential to have controlled humidity in your manufacturing facility.

- Another culprit for case board warp is the amount of moisture in the glue. The amount of glue applied to the board will affect the likelihood of warping. If you add more glue, you, in effect, add more moisture, which can accelerate the distortion because the porous board will absorb the water. You want to use the least amount of glue possible to achieve your desired adhesion. You can usually accomplish this by using high-quality glue, which requires a thinner application.

- The grain direction of the case board is another detail to pay close attention to. The grain direction is the direction in which most fibers are oriented. The recommended grain alignment in case-making is parallel to the book spine. Aligning the grains this way will help to limit the potential for warp.

Troubleshooting Case Board Warp

We hope this helped answer your questions regarding case board warp, but we understand that this is a nuanced issue with many possible factors. If you are still having trouble with board warp, compression, or box pop-opens, our technicians are here to help.

Thanks to our friends at Eska Graphic Board for their help on this post.

.jpg)