We’re pleased to announce that LD Davis is celebrating its 95th anniversary this year. Life and business are all about change. Over the decades, LD Davis has grown and adapted from a small, family-owned business to one of the largest glue manufacturers in North America.

Making a Mark on History with Adhesive

1926-1936

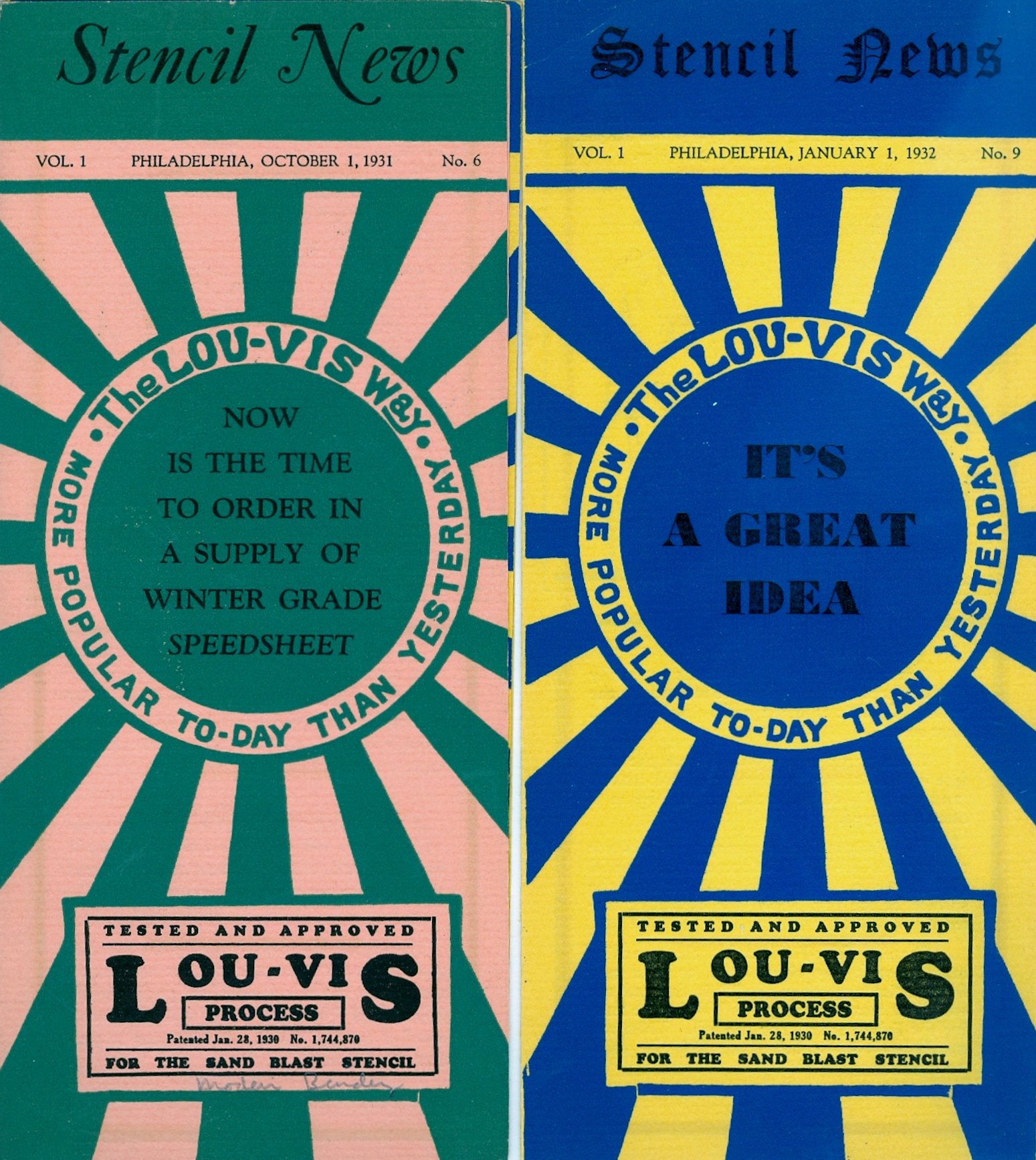

LD Davis was founded by entrepreneur Louis D. Davis Sr. in 1926. Initially, the company was headquartered in North Philadelphia and created products for stencil manufacturers. The original product was called the ‘Lou-Vis Adjustable Protecto-Curtain Speedsheet.’

The Lou-Vis sheets were used to make logos or designs on glass, stone, and other hard surfaces. The sheets were made from a mixture of glycerin and protein glue pressed onto a roll of burlap material with a piece of release paper pressed in between. The manufacturer would then cut the logo, name, or desired design out to the stencil sheet, heat the material, press it to the stone or glass surface, and then sandblast it to create a lasting image.

The Lou-Vis sheets were used to make logos or designs on glass, stone, and other hard surfaces. The sheets were made from a mixture of glycerin and protein glue pressed onto a roll of burlap material with a piece of release paper pressed in between. The manufacturer would then cut the logo, name, or desired design out to the stencil sheet, heat the material, press it to the stone or glass surface, and then sandblast it to create a lasting image.

Expanding and Adapting to Industry Needs

1936 - 1960s

One thing that has kept LD Davis moving forward as a company is our ability to change to industry demands. The stenciling business flourished for about a decade. The company moved to Bristol, PA, in 1936 to expand its operations.

One thing that has kept LD Davis moving forward as a company is our ability to change to industry demands. The stenciling business flourished for about a decade. The company moved to Bristol, PA, in 1936 to expand its operations.

By the end of the 1930s, however, the stenciling business wasn’t as profitable and could be performed by rubber alternatives. Fortunately, one of our main ingredients, raw glue, has a variety of uses. At the time, the packaging industry was using rigid boxes to move products.

Almost overnight, LD Davis shifted our products from creating stencil sheets to providing glue for rigid box manufacturers. From the ‘40s until the ‘60s, we became the primary provider of protein adhesive for rigid setup boxes, cotton-filled jewelry boxes, steamer trunks, and attache cases. By the end of the ‘60s, we expanded along with the packaging industry to offer adhesive for folding cartons and corrugated box manufacturing.

Changing Leadership and Focus

1970s - 1990

In 1977, the company’s ownership shifted to Louis D. Davis Jr. after the passing of his father. Louis D. Davis Sr.’s entrepreneurial spirit lives on, and our leadership team has expanded to address shifting industry needs. We brought in experts who helped develop our reach across the United States, Europe, and overseas.

In 1977, the company’s ownership shifted to Louis D. Davis Jr. after the passing of his father. Louis D. Davis Sr.’s entrepreneurial spirit lives on, and our leadership team has expanded to address shifting industry needs. We brought in experts who helped develop our reach across the United States, Europe, and overseas.

Our adhesives combine well with the requirements of the bookbinding industry, and by the ‘80s, we became one of the largest glue suppliers for binding books in the graphics industry. We continue to be a single source for all bookbinding glues for commercial and traditional applications, including hardcover, perfect binding, and seamless paperback books.

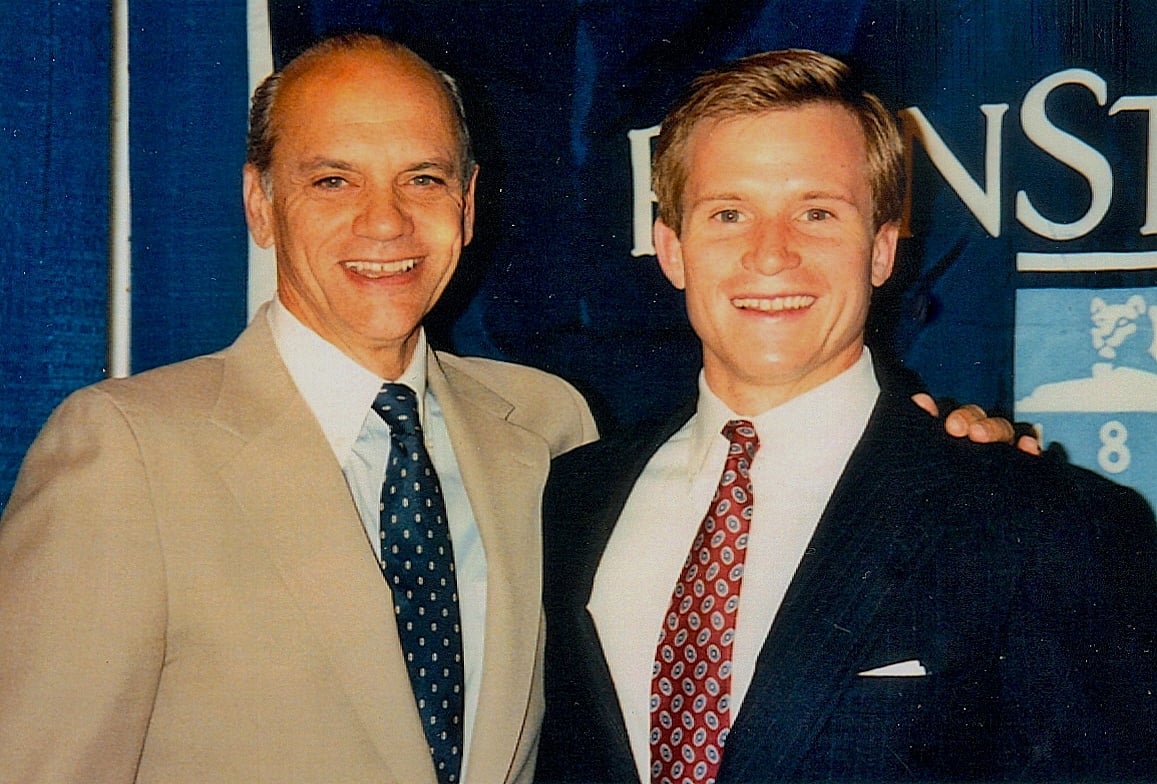

Over the decades, our focus at LD Davis has broadened to adapt to the needs of the bookbinding, rigid box, laminating, and food and beverage packaging industries. In 1990, ownership of the company transitioned to Tripp Davis, making him the third-generation owner of LD Davis.

Louis D. Davis Jr. (left) with Tripp Davis (right).

While we may still be a traditional, family-run company in some respects, we are continually seeking new opportunities for sustainable packaging growth. Under Tripp’s leadership, we are expanding our ability to be an environmentally friendly adhesives solutions supplier.

Eco-Friendly Glues for a Sustainable Future

Modern Day

Pharmaceutical netting pictured left and scored protein glue cakes on the right.

Pharmaceutical netting pictured left and scored protein glue cakes on the right.

Glue plays a role in nearly every package made. While the formulation of protein glue has changed a little over the years, the fact that it is biodegradable hasn't.

Yes, protein glue is an animal byproduct, but the vast majority of modern protein glue (also known as gelatin glue or jelly glue) comes from recycled pharmaceutical gel netting. LD Davis has been a leader in using recycled materials for adhesives from the very beginning.

Since the ‘70s, we’ve replaced our primary ingredient with recycled pharmaceutical and nutritional gelatin. This gelatin comes in the form of netting from soft gel nutrition pills and ground hard pharmaceutical capsules and is combined with other raw materials to make our glues non-toxic and environmentally friendly.

Discover more facts about protein glue production.

Recently, we’ve expanded our solutions to help reduce plastics and increase the possibilities of paper alternatives by providing adhesive solutions for paper straws, paper sleeves, and folding cartons. Reducing waste and creating a sustainable future means not just thinking outside the box but about the glue that holds everything together.

As we celebrate our 95th anniversary, we are excited to continue working with companies to create a more eco-friendly, plastic-free future. If you are interested in learning about our sustainable adhesives, let our experts know.