Wrap Size

How The Wrap Is Cut

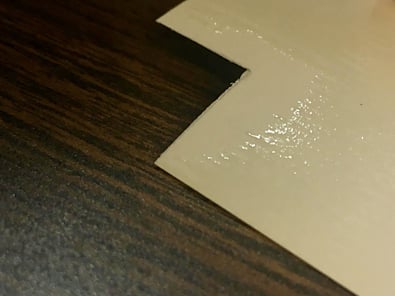

Depending on how your wrap is cut (and how sharp the blades are that cut it), you could run into issues where there is a small burr on the edge of the wrap.

Essentially, this is a small unwanted lip around the wrap that could make it difficult to apply glue evenly. As shown in the photo, burrs will make it difficult for the glue to meet the edge of the wrap. This will cause those turn-ins to pop open.

Dyne Levels of your Wrap

The Dyne Level of a material is called its surface energy. When glue is applied to the wrap, its “wettability” is impacted greatly by its surface energy and that of the wrap.

In order for glue to bond, it must be able to wet the surface of the wrap. For a wrap to bond well with protein glue the dyne level generally needs to be 45 or higher. Protein glue could work at lower dyne levels, but we would recommend speaking with our lab to perform glue ups to determine which glue would work best.

Looking for a convenient protein glue troubleshooting resource for your rigid box equipment operators? Our troubleshooting guide was so highly requested, we decided to turn it into a magnet!

You can keep this right on your machines as a resource for your team.