Our on-site research and development lab, located in Monroe, North Carolina, is dedicated to designing innovative and custom glue products.

Often times, prospects and customers reach out to us for help with formulating a glue for a difficult or custom application. For projects like this, our technical team will test sample substrates in our facility.

What happens with the substrates once they arrive in our lab?

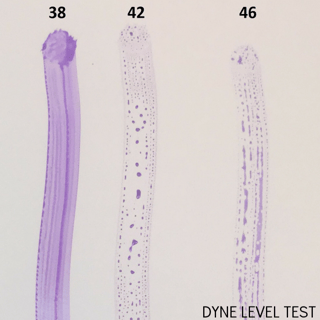

DYNE TESTS

A Dyne Test is performed to determine the surface energy of a material. This will help select the glue that is best suited to bond the substrates. This test is performed on the substrates using the Dyne pens. The lowest dyne level pen is used first, and then the next highest and so on. When the ink from the Dyne pen begins to bead then that signifies the level of surface energy of the substrate.

A Dyne Test is performed to determine the surface energy of a material. This will help select the glue that is best suited to bond the substrates. This test is performed on the substrates using the Dyne pens. The lowest dyne level pen is used first, and then the next highest and so on. When the ink from the Dyne pen begins to bead then that signifies the level of surface energy of the substrate.

When glue is applied to a substrate, its “wettability” is impacted greatly by its surface energy and that of the substrate. This is why dyne tests are so important.

In order for glue to bond, it must be able to wet the surfaces of the substrates. If it does not, poor bonding will results. For wetting to occur, the surface tension of the glue needs to be lower than the surface energies of the substrates.

Measuring the Dyne Level of substrates helps to identify problematic materials with very low surface tensions. For example, in order for a substrate to bond well with a protein glue,the dyne level generally needs to be 45 or higher. Protein glues can work at lower dyne levels but testing should be done with “glue-ups” to ensure a sufficient bond is obtained.

GLUE-UPS

Glue ups are performed to show the bonding capability of the selected glues to the substrates. This test is also performed to determine the speed of set to the material.

Glue ups are performed to show the bonding capability of the selected glues to the substrates. This test is also performed to determine the speed of set to the material.

This test is performed by cutting each substrate into small rectangular sections. Drawdowns are done on the substrates to apply the glue.

To ensure an even amount of glue is applied to each substrate, a drawdown board and a Myer rod are used. In this example, a number three Myer Rod was selected. This applies a 3-mil coating of adhesive on the substrate. The substrates were then bonded within two seconds of applying the glue.

The bond was made by applying medium pressure using a four-inch Speed Ball roller. The bonded substrates were then allowed to stand at room temperature for 24 hours. After this time the bonds were tested by pulling the bonded substrates apart. A successful bond occurs when there is failure (fiber tear) of one of the substrates. This indicates a complete permanent mechanical bond has been formed. If there is no fiber tear than the substrates are held together by a “suction bond”. This is a much weaker bond. These types of bonds are not permanent and are prone to fail.

HEAT & HUMIDITY TESTS

Heat and humidity testing is done for several reasons. This testing can be done to measure the amount of curl between the glue and a substrate. This can also be done to determine how well a bond will hold under extreme conditions.

After the substrates have been bonded together they are placed in a humidity chamber at the desired temperature and humidity. Typical testing temperatures range from room temperature to 120°F, but can be higher depending on the glue. Humidity can be

performed at 100% if need be. A typical time frame is 24 hours. The substrates are removed from the chamber and the bond is tested immediately.

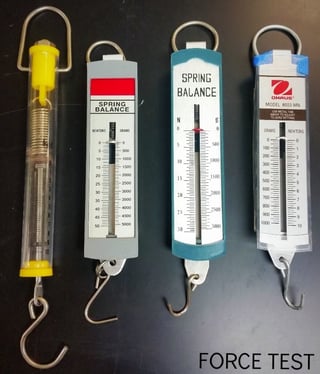

FORCE TEST

FORCE TEST

A force test is used to determine the amount of force it will take to separate the bonded substrates once they have been glued together.

The amount of force is measured in pounds’ force or Newtons by attaching a spring scale to one of the substrates and slowly applying a pulling force until the two surfaces separate.

FREEZER TEST

A freezer test is used to determine how well a bond will hold up under freezing temperatures.

Samples are placed in our freezer at the desired temperature for the desired time. Temperatures can reach as low as -40°F. The samples are removed and the bond is immediately tested for flexibility, strength, etc.

Want to speak with our lab experts about one of your upcoming projects?