Consumer brands are taking action to reduce their carbon footprint by setting sustainability goals. Often, these goals involve using a clean energy supply, sustainable use of resources, and sustainable transport. Ultimately, companies are focusing on shifting their processes to support a circular economy.

What is a circular economy?

A circular economy means that brands are designing products with a waste-out approach, whether that's creating recyclable goods, reusable goods, or compostable end-use products. There are different ways to approach reducing your carbon footprint from a manufacturing standpoint.

Many consumer packaging goods brands are taking steps to reduce waste by lowering manufacturing emissions and ensuring goods are packaged and disposed of in an eco-friendly manner. Using adhesives derived from raw or bio-based materials rather than petroleum is an effective and often overlooked way to reduce waste.

Defining Bio-based Adhesives

Bio-based adhesives come from natural, non-mineral, or non-petroleum sources and can be used in their current state or with slight modification and perform similarly to synthetic glues. Natural adhesives, especially those of animal or vegetable origin, have been known for thousands of years.

There has been less demand for bio-based adhesives since the mid-20th century with the rise of synthetic and polymer glues, but natural adhesives are often preferred when working with wood and paper products, including labeling and bookbinding. Gelatin-based glues are a type of bio-based adhesive that offers strong adhesion for wood and paper manufacturing while being biodegradable.

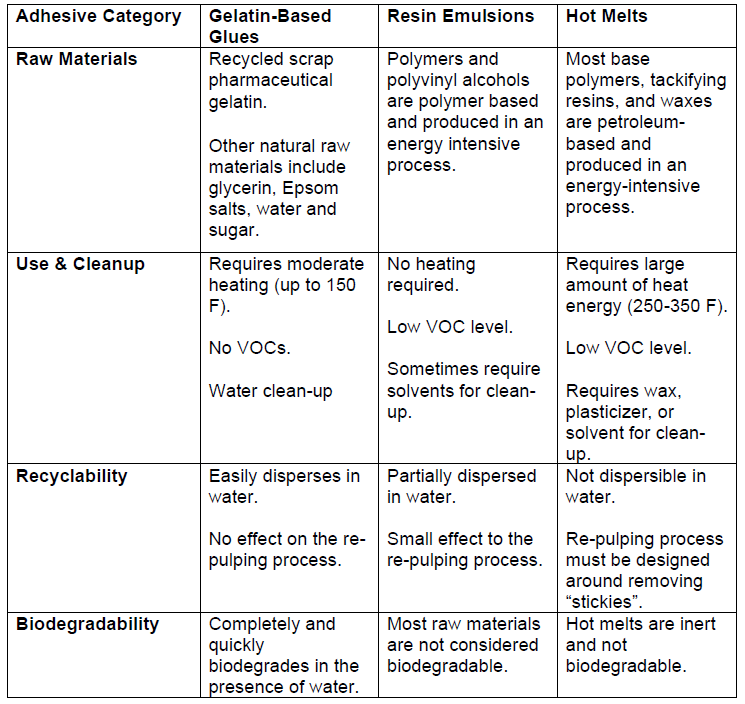

Gelatin glue is primarily composed of pharmaceutical-grade gelatin, sugars, Epsom salt, water, and glycerin. Since it is made from natural ingredients, mainly collagen, gelatin glue is biodegradable and does not affect the re-pulping process, unlike petroleum and polymer adhesives such as hot melt and resin.

The Environmental Impact of Different Adhesives

Improving Sustainability Practices with Gelatin-Based Adhesives

Gelatin adhesive is manufactured by recycling pharmaceutical gelatin used in soft gel and ground hard capsule production. This material is normally disposed of in a landfill, but pharmaceutical gelatin can be reused, creating a natural biodegradable glue while also diverting waste. While gelatin glue might have old connotations with past glue manufacturing processes, it is a highly-effective, modern process that offers a sustainable adhesive solution.

Benefits of Using Gelatin-Based Glues

- Non-toxic, biodegradable, recyclable, and re-pulpable

- Safe to handle

- FDA approved for indirect food contact

- Derived from recycled materials

- Reduces waste and conserves resources

- Water-soluble

- Excellent bonding properties

Choosing the Right Adhesives Solution

Gelatin glues offer companies a non-toxic, recyclable adhesive solution for laminating, rigid box production, case and carton sealing, book binding, and more. Depending on your manufacturing needs, adhesive ingredients can be modified to meet your requirements.

If you’re interested in improving your sustainability goals, our adhesive experts can help.